We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

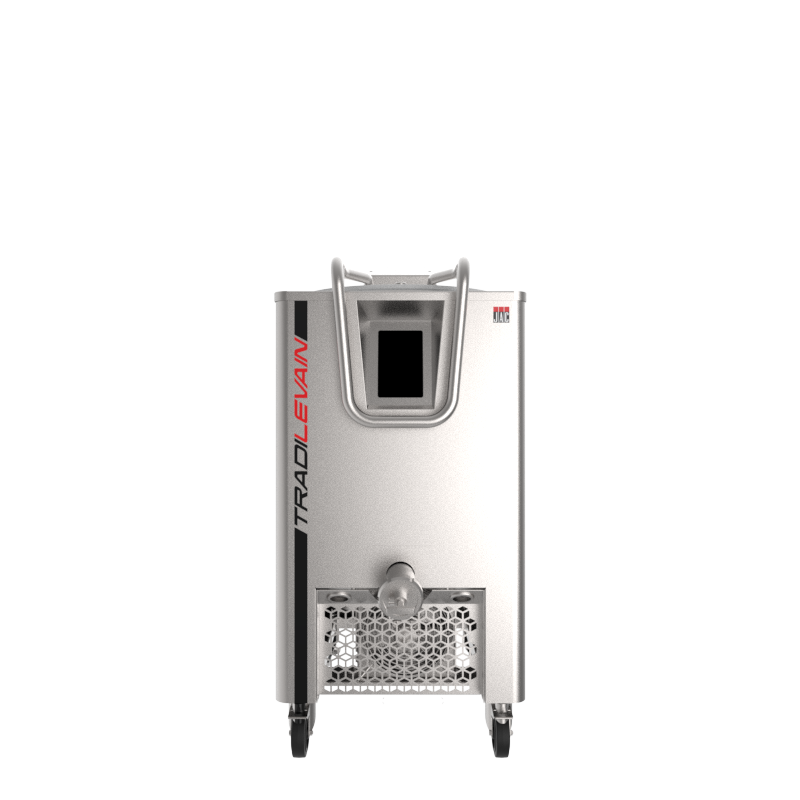

Sourdough fermentors

See all machines

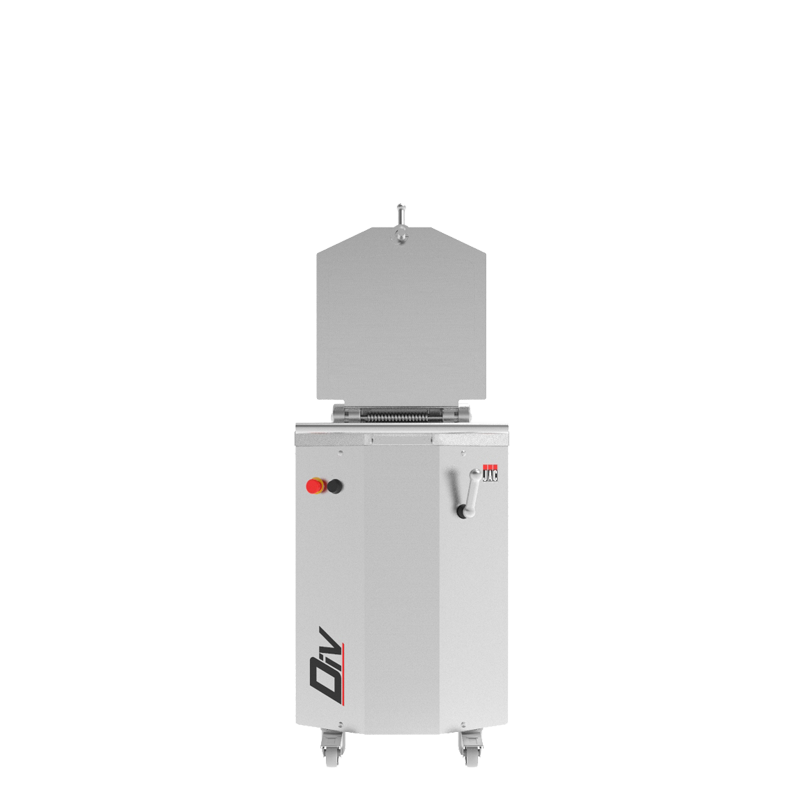

Hydraulic dividers

See all machines

Divider-moulders

See all machines

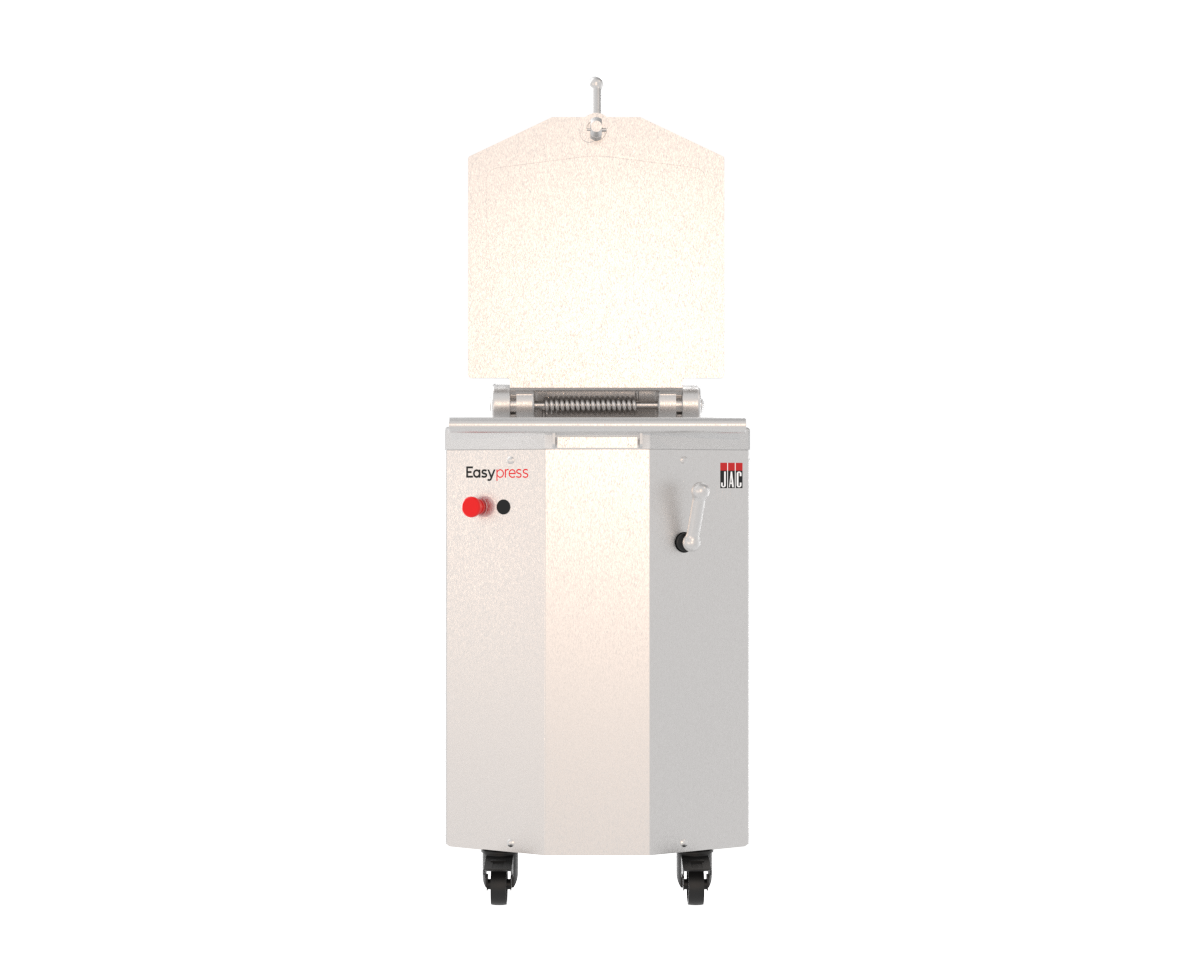

Butter and dough press

See all machines

Volumetric dividers

See all machines

Proofers

See all machines

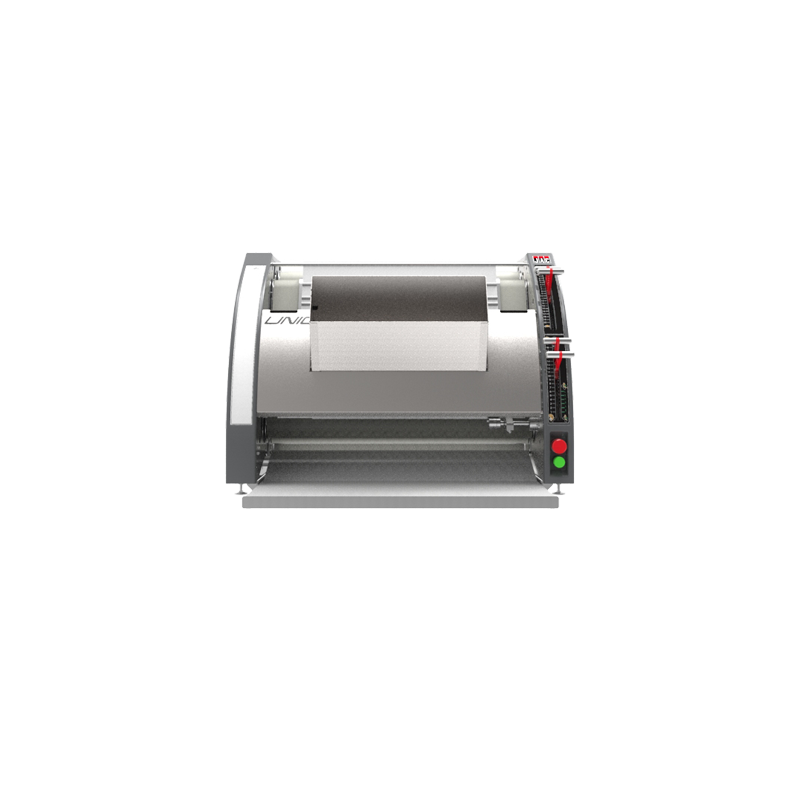

Moulders

See all machines

Automated production lines

See all machines

Meeting the demands of modern bakeries requires more than traditional craftsmanship—it calls for smart, automated solutions that support speed, consistency, and hygiene. A dough machine today goes far beyond mixing: it includes a wide range of specialized equipment designed to manage every stage of dough processing. From fermentation to portioning and shaping, these machines help streamline production while preserving the quality that defines artisan baking.

Far from being just a time-saver, the modern dough machine enhances precision, supports hygiene standards, and reduces physical strain. For both small-scale artisans and high-output producers, these machines have become a foundation for operational excellence. Their flexibility also allows bakeries to experiment with new product lines while maintaining efficiency on the core range.

A dough machine is no longer limited to kneading or mixing. It now describes any automated or semi-automated system that processes dough throughout its lifecycle—fermenting, dividing, resting, shaping, or preparing it for baking. These machines are built to optimize workflows, eliminate inconsistencies, and support bakers in producing flawless results, regardless of scale or dough complexity.

This broader definition reflects how the bakery industry is evolving: smart dough machines are no longer niche equipment but strategic assets that impact quality, cost management, and team productivity.

Dough machines have become indispensable across a wide range of baking environments:

In all these applications, the ability to replicate and scale recipes with absolute consistency has become a competitive advantage, especially in markets where brand trust is linked to product reliability.

To ensure optimal performance, always clean your dough machine after use using mild detergents and non-abrasive cloths. Lubricate moving parts as needed and check for wear on critical components. Store the machine in a clean, dry area, and schedule regular maintenance for longevity and reliability. A small investment in upkeep pays off in reduced downtime and improved daily performance.

From fermentation and dividing to shaping and proofing, today’s dough machines do more than support production—they enable growth. They reduce physical strain, streamline operations, and help bakeries of all sizes meet customer expectations with ease and confidence.

Upgrading to a high-performance dough machine means more than saving time. It’s about investing in consistent quality, scaling production efficiently, and allowing your team to focus on creativity and customer satisfaction. Whether you’re producing 500 or 5,000 loaves per day, there’s a dough machine built to help you rise.